Education

Arizona State University [Tempe, AZ]

Master of Science

Mechanical Engineering

Focus: Thermodynamics

Graduation year: 2024

EMBRY-RIDDLE Aeronautical University [Prescott, AZ]

Bachelor of Science

Mechanical Engineering

Energy Track

Graduation year: 2021

Key Courses [Masters level]

Advanced Thermodynamics

A deep understanding of thermal models, entropy analysis, exergy analysis, introduction to statistical thermodynamics, Maxwell relations.

Advanced Heat Transfer

Analytical transient models and solving complex models using comercial solvers (COMSOL). This course covers modeling human thermal management, freezing models, transient heating and cooling loads, thermal interfacing material (TIMs) used in semiconductors, evaporation models.

Refrigeration and Air Conditioning

Deep understanding of psychrometrics, air conditioning systems, refrigeration systems. Calculating heating/cooling load required and certain ASHRAE standards.

Experimental Methods Thermal Fluids Process

Knowledge on how to set up and run experiments, this includes signal processing, data acquisition, data analysis and knowledge of all the required components.

High Performance Computing (numerical modeling)

Using FORTRAN for high performance computing which includes understanding of implementing vectorization, multiprocessing (openMP), Message Passing Interface (MPI). Understanding of numerical modeling and setup to optimize processor distributed load.

Work Experience

2022 - 2024

FreshKube Inc. is a start-up that solves the partial load logistics in the cold chain. The partial loading of a refrigerated truck can increase the cost per kg of produce to a point at which small growers cannot get into the market. Freshkube's solution is to have small thermally insulated containers that can be stacked with all being connected to a central refrigeration unit that conditions each containers environment separately. This method allows different crops from different growers in the same truck due to isolated containers at different temperatures.

Design of Refrigeration Unit & Container

First year was spend designing and producing the first prototypes for demonstration. This includes the refrigeration unit and containers all done with minimal capital.

The refrigeration unit is designed to condition 2 containers in the Phoenix heat while being completely off grid. A deployable solar array was designed and made to increase the duration of the refrigeration unit and aid with precooling.

Design of Refrigeration Testbed

Responsible for the design and development of the refrigeration testbed at which research would be conducted on the effects of refrigerant charge in the system. Due to the highly variable cooling loads required at vastly different ambient temperatures research was conducted using design of experiment (DOE) to optimize the energy usage.

The experimental setup had to be done on a with minimal cost due to how the funded contract was set up. Majority of the components can be varied to measure the sensitivity of each components to the response variable.

The data acquisition system was made in-house using raspberry pi, amplifiers, ADCs ext. Shown below is the output of the system while charging the system and changing the electronic expansion valve accordingly.

There is a lot that can be concluded from this plot, which I will be more than happy to explain in detail.

Deployable Solar Farm (Patent)

The deployable solar farm is designed with a scissor like mechanism for easy deployment and also allows all 8 panels to have an optimal angle with one swift motion.

This design was filled in the U.S Patent office for a provisional patent with Dr. Villalobos (CEO) and Phillip Nielsen as Inventors.

Internship Summer 2019

Elo Automated Stainless Steel Technologies (Qingdao) Co., Ltd

The internship at Elo Automated Stainless Steel Technologies (EASST) I was given the task of finding possible ideas of new products that could be used in the refrigeration industry. One idea was to focus on making an economizer/subcooler that is less likely to fail due to its surroundings and could serve as another component. This design is still being studied and cannot discuss due to non disclosure agreement (NDA).

The internship consisted of traveling to Denmark for a meeting with MAERSK StarCool R&D and also visit EASST in china as shown below.

Brazing station at EASST manufacturing plant (China)

Projects

2017 - 2021

Heat Exchanger Test Rig

After graduation I volunteered to design and build a heat exchanger test rig with the great help of a thermal fluids lab assistants. The idea was for students to have a better understanding of heat exchangers and how they work in the real world since many students graduate without ever having tested or held one.

CAD model by Phillip Nielsen

Final Product of Test Rig.

The heat exchanger test rig is now implemented and being used for undergrad heat transfer course, at which students design and make their own heat exchanger to test and compete for the highest capacity.

Liquid Cooled Rocket Engine

Capstone

The capstone was to design and build a liquid cooled rocket engine, they assigned me the thermal lead which takes the responsibility of cooling the rocket engine. The rocket engine was cooled view channels of varying flow rates and geometry to ensure no super heated vapor at the exit due to reduced heat transfer coefficient in single phase flow.

The channels are formed when the other half is placed on top with the copper divider in between each channel as a separator. Shown below is how it looks all assembled on the liquid rocket test stand.

The video below shows the first test of the system, which is all done remotely and all the processes are automated. The cooling system starts first to ensure safe operation, then a liquid oxygen and fuel is primed. A hard start occurred which is an over pressurization which leads to a total failure of the system. The test stand has safety features to minimize the risk to the system. The bolts holding the chamber to the end plate sheared off releasing the chamber pressure in the form of a shock wave.

A lot was learned from the test, since hard starts in rocket engines happens even for large rocket companies. The capstone overall proved that a lot can be done with teamwork since only 6 months was used to bring the design to life and be tested.

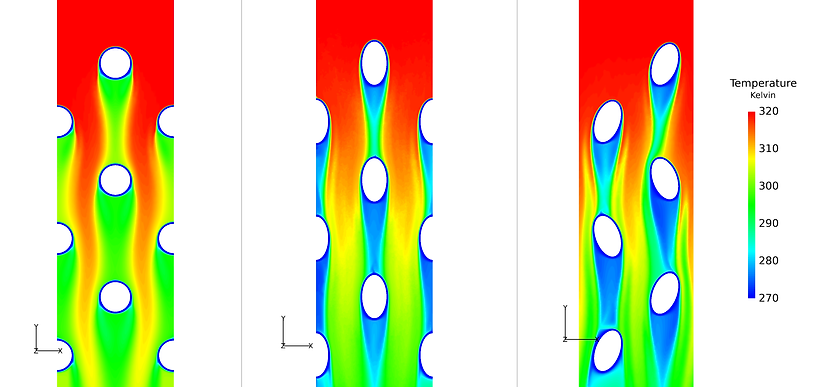

Studies of Oval Tube and Fin Heat Exchangers

I was an undergraduate research assistant at the Advanced Computing and Simulations Laboratory (ACSL) at which we had access to a suit of CFD solvers and pre and post processing software. I gained knowledge on CFD over the 3 years I was there and published findings of angled oval tube and fin heat exchangers. The alternating oval design proved best for heat transfer still lower pressure drop than simple circular design, this is still only a model and needs to be tested experimentally to prove worthy.